IIT and Camozzi Group started a Joint Lab in 2017 for developing a scientific and technological roadmap on new materials and advanced AI. PAVIS is collaborating in the activities related to the 5-year project focused on the digitalization of the production processes and quality control.

In collaboration with IIT AIAL (https://advr.iit.it/index.php/research/aial), PAVIS is developing a solution for the automatic inspection of large industrial machines based on automatic AI algorithms. The solution aims at providing an automated inspection solution both in planned and unplanned maintenance procedures. Automation of the inspection processes would introduce multiple benefits, including the risk reduction of the human operators and the possibility to create digital twins for a deeper analysis and study of predictive maintenance approaches.

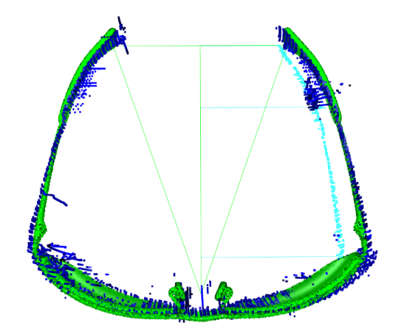

In collaboration with a World leading eyewear company, PAVIS studied and developed a highly automated quality control solution. Goal of the developed system is to support the employers' activities during eyewear inspection, in order to improve their comfort during the operations and optimize the production pipeline maintenance.

The developed solution consists in a robotic arm inspecting the finalized eyewear. The acquired images and laser scans are processed by AI algorithms to detect the presence of aesthetic or geometric defects.

Automatic Part Checking

This project, in collaboration with AVIOAERO, involves the automatic inspection of complex mechanical parts. This project is devoted to the development of Machine Vision algorithms to automate highly time-consuming and critical quality inspection processes in the aeronautic industry. In this industrial context of automated quality inspection, we addressed several quality assessment problems like damage detection, aesthetic evaluation and multi-camera visual inspection.

Visual Inspection

This project in collaboration with AVIOAERO, is related to the visual inspection of the oil ducts inside an aerospace mechanical piece using an endoscopic camera sensor. This project provides a complete system for an automatic visual inspection, capable to detect, recognize, and remove the eventual debris that is present in the duct due to previous production process. Inspection inside the very thin ducts (up to 2.5 mm) is performed using a digital borescope camera handled by a robotic arm.

This project is in collaboration with OMRON and aims to develop methods for (i) 6D pose estimation from a single RGB image for complex texture-less objects as well as (ii) autonomous exploration techniques for robots in unknown environments by means of a moving RGB-D camera. The former problem is addressed by means of a novel part-based method using an efficient template matching approach where each template independently encodes the similarity function using a Forest trained over the templates. The latter problem addresses the 3D perception by autonomous robots using highly efficient Simultaneous Localization and Mapping (SLAM) techniques.

IIT addressed a research project with Brunello Cucinelli company involving optics, computer vision, and physical simulations to enhance the textiles quality inspection, to improve safety and to reduce costs. The project involved: (i) detection of defects in complex regularity patterns on textiles using deep learning, (ii) verification of structural integrity of mass-produced, highly deformable items, (iii) checking that the fabricated item respects the industrial standards and procedures (this project was funded by the "The Contemporary Factory Regional Operational Programme – European Regional Development Fund (ROP-ERDF) ROP-ERDF 2014-2020)